6吋SPI H-Series簿膜式壓力分布實機Demo

超敏壓力,超簿膜 (具NIST Traceable認証)

超敏壓力分析篇 Web Link: youtube.com/watch?v=cqYyxBoyC0U

超簿膜厚度可達0.3mm

耐高溫 0~93℃

不易磨損,感測器保修一年

1~19 英吋

可設定多種量程,保證精確度

使用方便

感測器出廠前單獨校準,無需自校

出貨時也提供美國NIST數據認証書

USA SPI H-SERIES 6inch壓力分析,

0.3mm的薄膜力量感測技術,

最新的薄膜壓力原件簿膜壓力感應, 超敏感感測器,

其壓力分析量程可以很小,

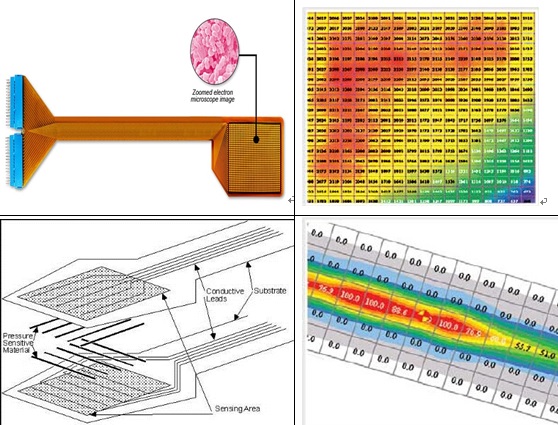

軟體介面上即時顯示每個感測單元的壓力值;

可分析接觸面積的壓力分佈狀況,以二維和三維圖形顯示,

以藍綠黃紅等基色顯示最小值至最大值圖形,

可顯示壓力與時間曲線

薄膜型感測器

0.3mm

掃瞄頻率高

0-200Hz

出廠校驗報告

由NIST美國國家標準與技術研究院檢測,

並出具校驗證書高溫耐奈米聚合物材料製造,

-50℃-93℃耐用非易耗品可保修一年

客制化產品規格

可根據客戶需求定制不同外觀感測器

軟體介面強大功能

即時性顯示2D和3D畫面

256階RGB漸變色顯示圖形

軟體可即時顯示每個壓力感測點的數值

顯示壓力平均值、最大值、最小值

顯示感測器受力中心點,可追蹤軌跡

錄製整個測試過程,載入錄製檔後可還原測試過程

隨時錄製與停止,快進、後退、慢速播放

顯示壓力與時間曲線

Kg/cm2,RAW,PSI,ATM,mmh,Kpa,bar等力學單位輸出

The Innovation

The exciting advancements in Nano-materials have allowed us to introduce

the world’s first nano-polymer based tactile surface sensor.

With greater temperature resistance, more accuracy, less drift and better repeatability

the user now can perform surface mapping analyses with greater confidence than ever before!

What It Does

Tactilus® allow the user to capture and record pressure conditions occurring in between any two contacting

or impacting surfaces in real time. The paper-thin Tactilus sensor is actually placed at the contact interface

where it records and assimilates both pressure distribution and pressure magnitude on your Windows® based computer.

軟體介面強大功能

即時性顯示2D和3D畫面

256階RGB漸變色顯示圖形

軟體可即時顯示每個壓力感測點的數值

顯示壓力平均值、最大值、最小值

顯示感測器受力中心點,可追蹤軌跡

錄製整個測試過程,載入錄製檔後可還原測試過程

隨時錄製與停止,快進、後退、慢速播放

顯示壓力與時間曲線

Kg/cm2,RAW,PSI,ATM,mmh,Kpa,bar等力學單位輸出

| SPECIFICATIONS | ||

Active Technology Nano-tubes Composite |

Scan Speed Up to 800 FPS |

Accuracy ± 10% |

| Surface Pressure Range *0 - 150 PSI (0 - 10.5 kg/cm²) |

Temperature Capability Up to 200° F (93° C) |

Repeatability ± 2% |

| Matrix Size Up to 32 x 32 lines |

Spatial Resolution From 0.06 in. (1.6 mm) |

Hysteresis ± 5% |

| Sensing Points Up to 1,024 total |

Thickness 16 mils (0.4 mm) |

Non-linearity ± 1.5% |

| Sensing Area Size Up to 14 x 14 in. (35.6 x 35.6 cm) |

*Sensors larger than 8 x 8 in. have max pressure capabilities that are lower. System includes: Sensor element, Signal conditioning electronics, and Software |

|